Experienced welders who can pick up a stinger, pop an electrode in and lay down great welds time after time can inspire great awe in the rest of us. Flash comes from the ultraviolet light that the welding rod creates. Q: How big of machine do I need? I could not believe my eyes! If you don't, you're hurting your chances to make a good weld the first time. Unclean conditions can lead to cracking, porosity, lack of fusion or inclusions. To cover a wider area, make multiple passes or use stringer beads.

On thicker metals you also want to preheat the aluminum to at least 500 degrees. A: A 225- to 300-amp handles almost anything the average person will encounter, as most stick welding procedures require 200 amps or less. A separate filler rod, held in the welder's other hand, is added to fill the puddle. This slight angle will prevent slag from overtaking the tip of the electrode, as welding over the slag might cause inclusions to form in the weld. Stick Electrode Angle Overhead Welding Defying Electrode Angle Rules Below are two pictures I of weld I did dragging uphill instead of pointing my electrode up.

The inclusion of hydrogen will cause the welded area to become brittle. Step 4: Find Your Angle: As you drag or backhand the arc down the base metal, you have to make sure to maintain your arc distance. But basic shielded metal arc welding, site or stick welding, has solved dozens of other smaller problems at duck camp, from fixing the floorplate on an old pump gun to boat and auto repair. Because of their driving arc, E6010 electrodes do not need much additional control intervention. In order to submit a comment to this post, please write this code along with your comment: f6e1c9242a3ecacfc4ba85389ed4fbec.

A 7018 is 70,000 pounds of tensile strength per square inch. This is the deposit of metal that joins the two pieces that you are welding together. What should you concentrate on when laying down a bead after an arc has been established? Finally you put a welding rod into the electrode holder and strike the area like a match where you want to start to weld. It sounds simple, but welding is a delicate dance between heat, filler rod and puddle control. When you power, wire speed and travel speed are all in line you welding will make a sound similar to cooking bacon, a nice steady sizzle. It's important to concentrate on maintaining your arc length, and the size of your molten pool.

At 130 amps you can weld unlimited thickness metals. There are two techniques to use in striking the arc: scratch-strike and tapping. Note toward the end of the bead in the image below how the bead appears inconsistent as if the puddle were trying to keep up. Note that the penetration remained relatively constant for Welds 7-9. Marketing Google AdSense This is an ad network.

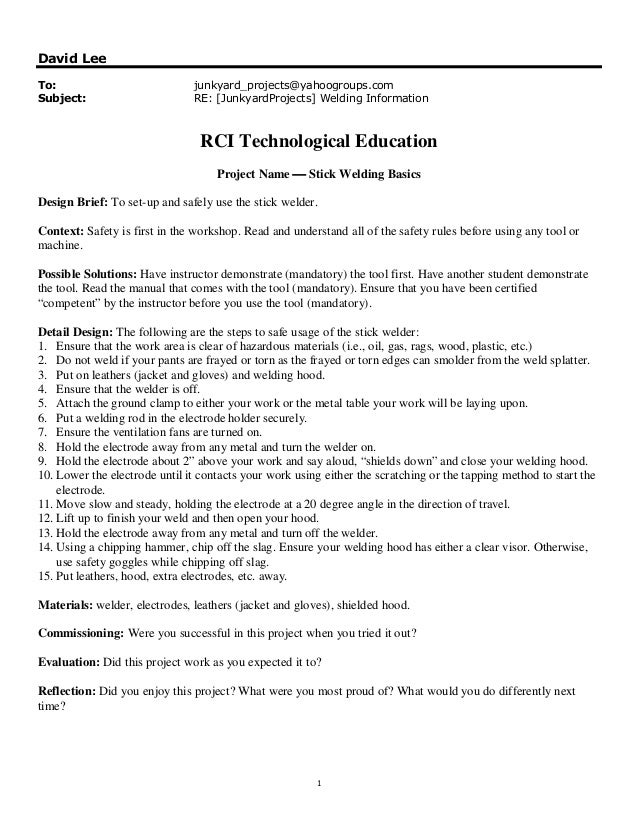

Learn the steps for creating a successful weld. Prepare the metal to be welded. Variables such as wind and moisture can have adverse effects on weld quality. A sign of too much current is when the electrode becomes hot enough to glow. Excessively long arcs too much voltage produce spatter, low deposition rates, undercuts and sometimes porosity. The electrode holder is sometimes called the 'stinger' because it sort of looks like one. Welding Electrodes: These are wire rods of various diameters, metals and alloys covered in a flux coating.

Before welding on the material that is to be your finished product. The final product after welding has all the properties retained as that in metals. This allows for better penetration. Q: What type of stick welder works best for all-around use? This is the only time you will want a long arc like that. The picture above shows how it welds.

Direct current is where the the electrons flow in one direction only. High-quality welds are possible in this labor-intensive process. Welding Current The variable of welding current primarily controls the amount of weld metal that is deposited during welding. As a good starting point, arc length should not exceed the diameter of the metal portion core of the electrode see. First you need to hook up your welding rod holder and ground clamp to the welding power supply. Long arcs also often leave porosity.